As part of an urban infrastructure upgrade, a local utility contractor in Ulaanbaatar initiated a gas distribution network improvement project to support residential and small commercial users. The project required a piping system capable of withstanding low temperatures, seasonal ground movement, and long-term underground installation.

Location: Mongolia

Project Period: 2022

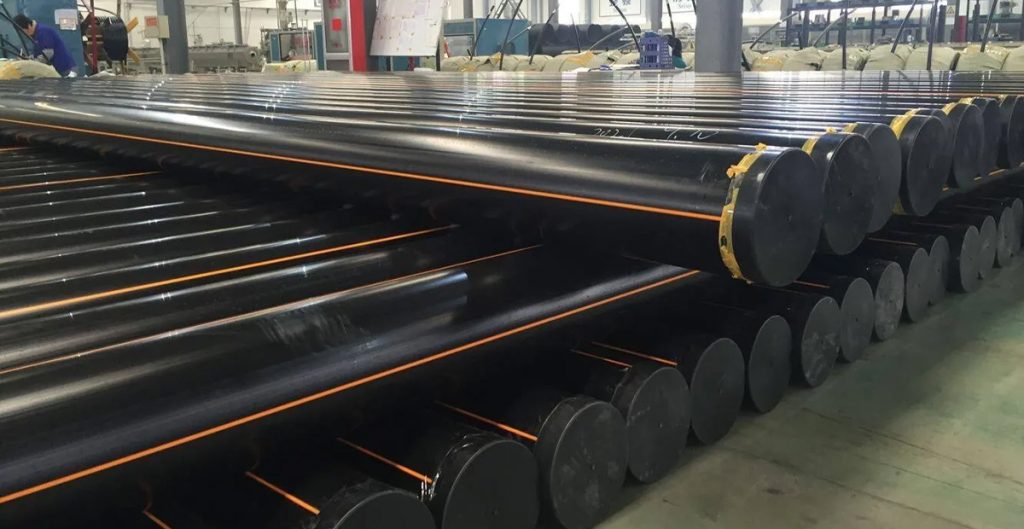

EXLON PIPE supplied HDPE Gas Pipes and matching fittings, manufactured in accordance with relevant international standards and tailored to the project’s pressure and dimensional requirements. Considering Mongolia’s climate conditions, material stability and joint reliability were key selection factors.

Beyond product supply, EXLON PIPE provided technical consultation on pipe selection, jointing methods, and installation practices, helping the contractor optimize system safety and construction efficiency.

Project Value

- The supplied HDPE gas piping system offered strong resistance to corrosion and cracking, supporting safe underground operation in cold environments.

- Stable production planning ensured continuous delivery aligned with the contractor’s phased construction schedule.

- Clear documentation and responsive communication reduced coordination time during procurement and installation.

Mongolia’s extreme winter temperatures and seasonal ground movement increased the risk of brittle failure and joint stress. To address this, EXLON recommended PE100-grade material with improved low-temperature impact resistance and provided electrofusion fittings specified for cold-climate performance. We also issued detailed jointing and cold-weather installation guidelines and held a one-day on-site technical briefing for the installation crew to ensure correct fusion practices under subzero conditions.

All supplied pipes and fittings were manufactured under EXLON’s standard quality controls and accompanied by material certificates and test reports. Prior to shipment, batches underwent dimensional checks, hydrostatic pressure testing at factory level, and visual inspection. After installation, the contractor conducted pressure tests on each new section; EXLON’s technical team reviewed test results and helped interpret remedial steps where minor issues were found.

Given limited storage at the urban sites and tight seasonal work windows, EXLON coordinated flexible delivery windows and repackaging to facilitate local handling. Clear labeling and delivery documentation reduced on-site sorting time and prevented installation delays.

The upgraded network improved distribution reliability and reduced leak risk in cold months. The client reported smoother construction progress due to timely deliveries and practical installation guidance, helping the municipality complete the phased upgrade within the planned season.