HDPE Gas Pipe

- Water supply field

- Agricultural irrigation field

- Mining field

- Construction sector

Complete control over products allows us to ensure our customers receive the best quality prices and service.

SEND EMAIL| Size | Size | Diameter | Socket Depth | Wall Thickness |

| mm | Inch | Tolerance | (mm) | |

| DN | DN | (mm) | W. T. | |

| 20 | 1/2” | 0.2 | 1.7 | |

| 25 | 3/4” | 0.2 | 1.7 | |

| 32 | 1” | 0.2 | 1.8 | |

| 40 | 1 1/4” | 0.2 | 2 | |

| 50 | 1 1/2” | 0.2 | 75 | 2.4 |

| 63 | 2” | 0.3 | 100 | 3 |

| 75 | 2 1/2” | 0.3 | 110 | 3.6 |

| 90 | 3” | 0.3 | 120 | 4.3 |

| 110 | 4” | 0.4 | 120 | 4.2 |

| 125 | 5” | 0.4 | 119 | 4.8 |

| 140 | 5 1/2” | 0.5 | 125 | 5.4 |

| 160 | 6” | 0.5 | 132 | 6.2 |

| 180 | 6” | 0.6 | 145 | 6.9 |

| 200 | 8” | 0.6 | 145 | 7.7 |

| 225 | 8” | 0.7 | 152 | 8.6 |

| 250 | 10” | 0.8 | 160 | 9.6 |

| 280 | 10” | 0.9 | 170 | 10.7 |

| 315 | 12” | 1 | 180 | 12.1 |

| 355 | 14” | 1.1 | 180 | 13.6 |

Yes, our heavy-duty series is engineered specifically for direct embedding in structural concrete. With a high pressure rating and superior impact resistance, these rigid PVC pipes maintain their structural shape even under the intense vibration of concrete installation. This reliability protects your internal wiring from being crushed or pinched during the curing process, ensuring a clear and unobstructed path for all future cable routing and maintenance.

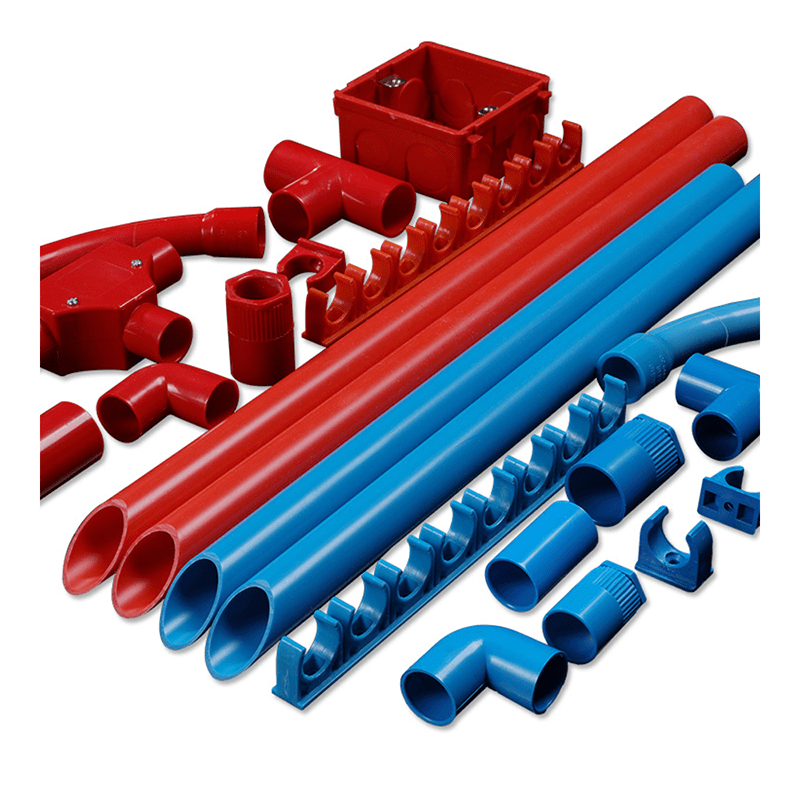

We offer a comprehensive range of compatible PVC electrical fittings, including couplings, elbows, and solvent cements, ranging from DN20 to DN250mm. This integrated system approach ensures that every connection point remains watertight and mechanically secure. Providing a one-stop procurement solution minimizes compatibility risks on-site, allowing your engineering team to focus on installation efficiency rather than sourcing missing components from multiple suppliers.

Backed by 25 years and 116 production lines, EXLON PIPE ensures disciplined quality and stable supply reliability.

CE/ISO compliant

Tailored designs

Volume discounts

Full fittings range

Stable supply chain

Full-Process Fast Response

Get In Touch

We support engineering contractors and project procurement teams with HDPE & PVC pipe solutions across Africa, the Middle East and Latin America. Let us know your project requirements and we will respond promptly.

Get In Touch

We support engineering contractors and project procurement teams with HDPE & PVC pipe solutions across Africa, the Middle East and Latin America. Let us know your project requirements and we will respond promptly.